Connecting a wideband O2 sensor to the Ram Jet 350 Engine

I have been tuning the Ram Jet 350 engine using an Innovate LM-1

wideband O2 sensor. The sensor for the LM-1 is attached to the exhaust system just below

the passenger side exhaust manifold. Initially I tried tuning the engine by

observing the O2 sensor readout on the LM-1 while, at the same time, observing the other

engine parameters using ScannerPro equipped with MEFI4a definition files supplied by OBD

Diagnostics, Inc.

I quickly realized that in order to properly tune the engine I would

need to be able to data log the O2 sensor readings along with all the other engine

parameters using ScannerPro. The LM-1

wideband has two analog outputs which are programmable.

I programmed the LM-1 analog 1 output to send 0v at AFR=10 and 5v at

AFR=20.

The MEFI4a controller has several unused input lines and I chose to

use pin J2-20 which is an oil pressure input. The

LM-1 analog output 1 connector has a positive line which I connected to J2-20 and a ground

which I connected to a ground terminal on the MEFI4a controller mounting bracket.

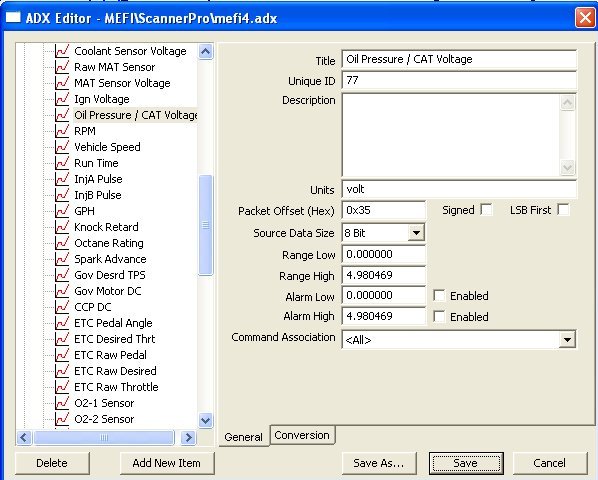

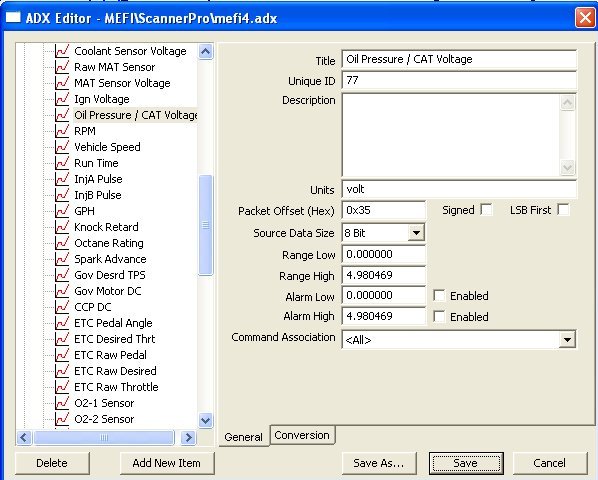

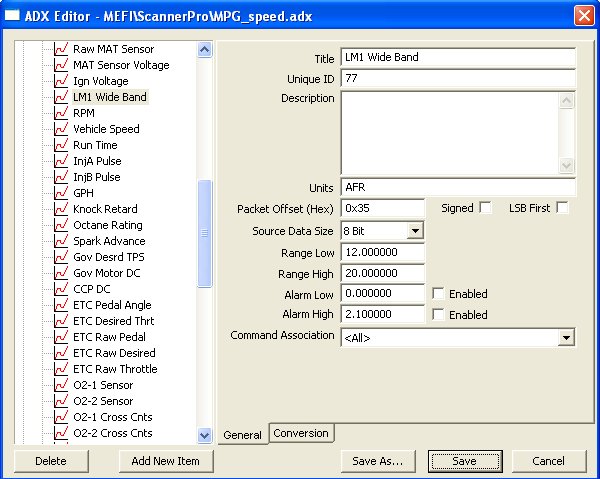

To check the voltage from the LM-1 analog 1 output I changed the dashboard display of ScannerPro to display “Oil Pressure/CAT voltage”. This resulted in the correct voltages being displayed, but I needed the display to show this value as an A/F ratio. I used the “edit definition” feature in ScannerPro and modified the “Oil Pressure/CAT voltage”. When you open this value in ScannerPro the definition looks like this:

The Packet Offset (Hex) value of 0x35 is the location of the oil pressure data packet in the data stream from the controller. Click on the "Conversion" tab near the bottom of the window and the following screen will appear:

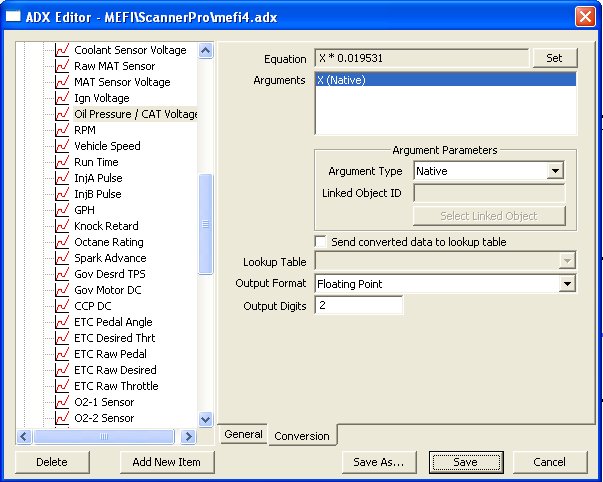

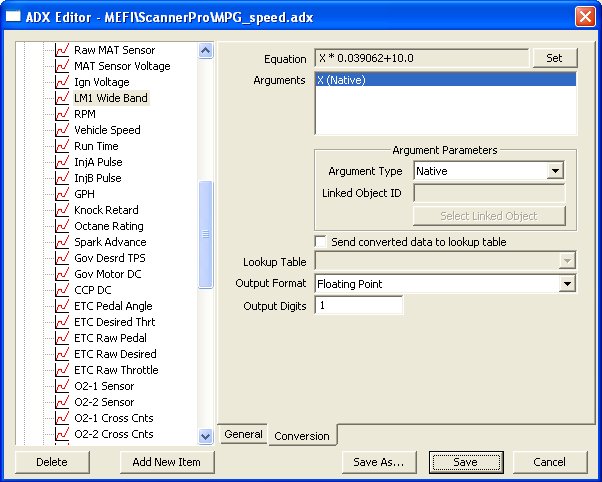

The Equation at the upper right corner of the window is X * 0.019531. This is the equation for converting the digital output of the MEFI4a controller (actually a value from 0 to 255) into a voltage. So the displayed voltage equals the raw value (a number from 0 to 255) * 0.019531 and the maximum value would be 255*0.019531=4.98v. To change the voltage to an air/fuel ratio modify the values in the "Conversion" window to read as shown below:

The number 0.039062 is the original conversion factor (0.019531) * 2, since we actually want the voltage to represent values from 0v to 10v and, since 0v equals an AFR of 10, we have to add 10 to the voltage to get the correct AFR reading.

I also changed the values in the "General" window to those shown above so that Oil Pressure gauge in ScannerPro would now be labeled "LM1 Wide Band" and the displayed units would be AFR instead of volts.

This method of connecting a wide band to the MEFI4a is for data logging purposes only and the wide band does not in any way control the AF ratio in the engine.